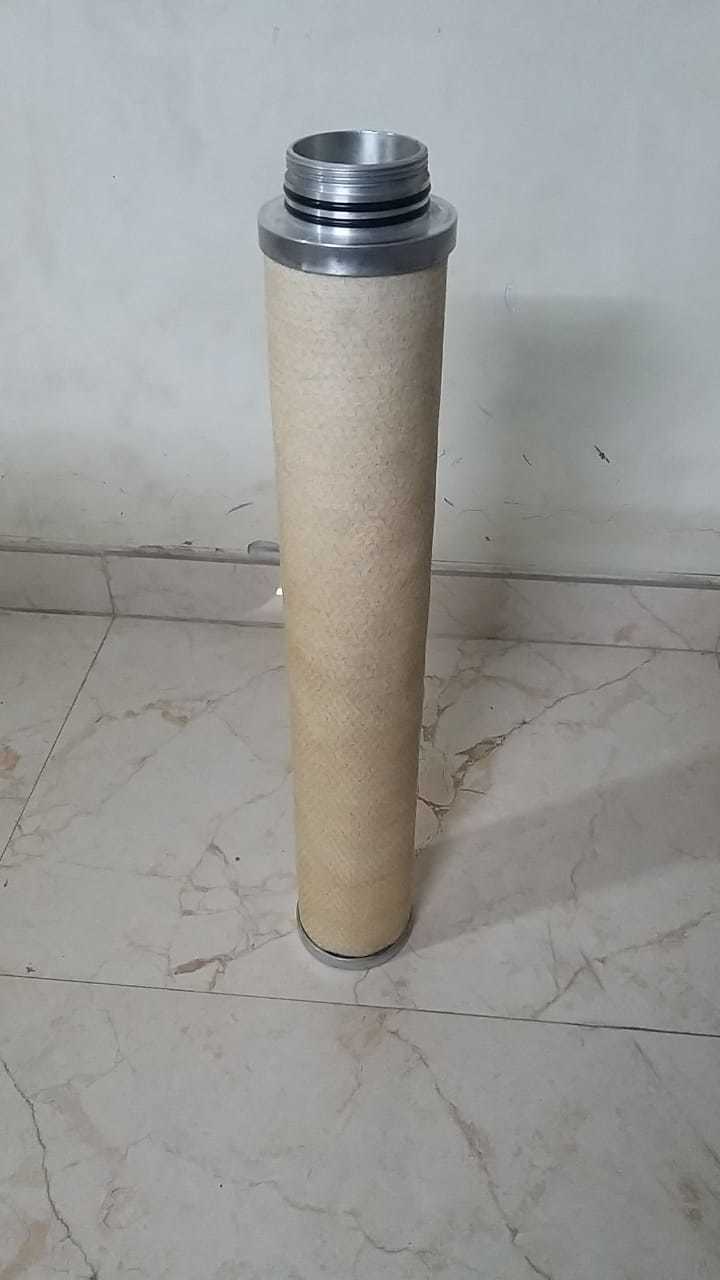

Coalescing Filter Element

Coalescing Filter Element Specification

- Condition

- New

- Usage

- Air, Gas and Liquid Filtration

- Material

- Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

- Mesh

- 0.01 Micron to 6000 Micron & More

- Diameter

- 25 Millimeter (mm)

- Height

- 55 Millimeter (mm)

- Product Type

- Filter Element

- Construction

- Wire Mesh

- Filtration Grade

- Others

- Color

- grey

- Width

- 25 Millimeter (mm)

- Length

- 40 Millimeter (mm)

- Medium Filter

- Other

- Weight

- 500 GSM (gm/2)

Coalescing Filter Element Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 200 Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Cardboard Box

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Coalescing Filter Element

Coalescing Filter elements made of various filter medias like paper, synthetic, polyester, pp, coalescing, borosilicate glass fibre, activated carbon, HDPE, non-woven, stainless steel wire mesh, sintered bronze, sintered wire mesh and sintered powder. We also offer scrubber system for moisture separation from air and gas.

Air/Gas Filter classified under below categories.

a) MS Moisture Separator

For the removal of 99% of bulk oil/water removal from the compressed air.

b) SB Pre Filtration

Sintered bronze filter elements for removal of pipe scales, bulk liquid, solid p[articles, dust down 5 micron. This filter elements available in 5, 10, 25 and above microns.

c) PF High Efficiency Fine Filter

For the removal of particles down to 1 micron including coalesced liquid water and oil, dust, providing a maximum remaining oil aerosol content of 0.5 mg/m at 21 C.

d) UF High Efficiency Oil Removal Filtration

For the removal of particles down to 0.01micron including oil aerosols, dust, providing a maximum remaining oil aerosol content of 0.01 mg/m (0.01 ppm) at 21 C efficiency 99.99% (install in series with filter type PF). [Borosilicate glass microfibers filter media which actively repel oil to reduce pressure drop and running cost to an absolute minimum.]

e) AC Activated Carbon Filtration

For the removal of vapour and hydro carbonod ours giving a maximum remaining oil content of <0.003 mg/m(<0.003 ppm) (excluding methane) at 21 C(install in series with filter type PF + UF).

Advantages:

- Easy to clean

- Low Pressure drop

- Large area

- Easy to operate and maintenance

- Positive Sealing to prevent bypass

- Customized design

- High dirt load holding capacity

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

Versatile Material Selections

Choose from a variety of materials including Aluminium, Carbon Steel, Mild Steel, and different stainless steel grades (SS304, SS304L, SS316, SS316L, SS317L) to meet specific chemical compatibilities and mechanical requirements. These options allow a tailored approach for diverse industries, enhancing durability and filtration efficacy.

Precision Filtration Capabilities

With mesh sizes ranging from an ultrafine 0.01 micron up to 6000 micron, this coalescing filter element meets the demands of both fine and coarse filtration. This flexibility ensures reliable removal of particulates from air, gas, or liquid streams, making it suitable for a wide variety of process conditions.

Engineered Construction and Dimensions

Manufactured in a sturdy wire mesh design, the filter element measures 25 mm in diameter, 40 mm in length, and 55 mm in height. It is delivered in a compact, robust format, suitable for integration into new filtration systems or for retrofit in existing setups, offering easy compatibility and installation.

FAQs of Coalescing Filter Element:

Q: How does the coalescing filter element work in air, gas, and liquid filtration?

A: The coalescing filter element captures and aggregates fine particles, separating solid contaminants and coalescing aerosols into larger droplets for easier removal. The wire mesh construction and broad micron range help ensure efficient filtration across various media including air, gases, and liquids.Q: What materials are available for the construction of this filter element?

A: This filter element can be made from several materials, such as Aluminium, Carbon Steel, Mild Steel, SS304, SS304L, SS316, SS316L, and SS317L. These choices provide flexibility for different environmental conditions, chemical exposure, and filtration requirements.Q: When should I consider replacing or upgrading my filter element?

A: Replace or upgrade your filter element when you observe increased pressure drop, degraded filtration efficiency, or as part of a scheduled maintenance routine. Using the filter in its optimal condition ensures better protection for your systems and higher process reliability.Q: Where can I use these coalescing filter elements?

A: These filters are suitable for use in a wide range of industrial settingsacross air, gas, and liquid filtration systems in manufacturing, processing plants, and utility facilities throughout India and internationally.Q: What are the benefits of using a 0.01 micron to 6000 micron mesh range?

A: A broad mesh range enables precise filtration tailored to the specific requirements of your process, allowing for efficient removal of both ultrafine particles and larger contaminants, ultimately leading to enhanced product quality and reduced equipment wear.Q: Can you describe the process for selecting the right filter mesh size?

A: Selecting the correct mesh size involves evaluating the size of contaminants to be removed, process flow rates, and compatibility with media. Consulting with the manufacturer or supplier is recommended to match filter performance to your application needs.Q: What makes this filter element advantageous for exporters, importers, and manufacturers?

A: Its customizable materials, wide mesh size spectrum, compact size, and robust new condition make it highly versatile for diverse industrial needs, facilitating easier sourcing, installation, and compliance with various quality standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Filters Category

Gas Filter

Price Range - 300000.00 / Piece

Minimum Order Quantity : 1 Piece

Construction : Cartridge Filter

Mesh : 0.01 Micron to 6000 Micron & More

Condition : New

Conical Strainers

Minimum Order Quantity : 1 Piece

Construction : Wire Mesh

Mesh : As per Design

Condition : New

Industrial Gas Filter

Price Range 10000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 2 Pieces

Construction : Other, Robust welded structure

Mesh : Fine mesh (customizable by application)

Condition : New

Coalescing Filters

Price Range 5000.00 - 9500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Construction : Other

Mesh : 0.01 Micron to 6000 Micron & More

Condition : New

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free