Micron Cartridge Filter

Price 1000 INR/ Piece

Micron Cartridge Filter Specification

- Sealing

- Gasket, Oring

- Filter Rating

- 0.2 to 6000 Micron

- Pore Size

- Customized

- Shape

- Customized

- Usage

- Air, Gas, Liquid

- Product Type

- Industrial

- Size

- Customized

- Length

- 50 to 3000 Millimeter (mm)

- Application

- Air, Gas and Liquid

Micron Cartridge Filter Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Cardboard Box, Wooden Box

- Certifications

- ISO 9001:2015

About Micron Cartridge Filter

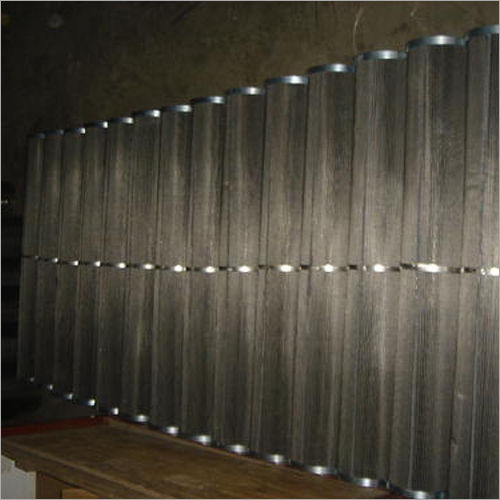

Micron Cartridge Filter

PVDF, PP or N66 material fabricated Micron Cartridge Filters are reckoned for their excellent flow volume, low differential pressure and high filtration capacity. Application of these products can be noticed in food processing, electronic, pharmaceutical and chemical fields. These filtering solutions are compatible with chemicals and these have excellent water flow capacity. Simple to install, maintain and clean, these can be used for various filtration jobs. All the raw materials used for these filters are free from harmful BPA and are approved by FDA. What is more, these have unique pressure endurance performance. We are a successful manufacturer and exporter of Micron Cartridge Filters.

Product details

| Length | 10 - 30 Inch |

| Usage/Application | Industrial |

| Brand | Guru |

| Operating Temperature | 80 to 150 Deg. C |

| Shape | Round |

| Particles Removal | 1 Micron to 6000 Micron & More |

| Diameter | 6 - 12 inch |

| Filter Medium Material | Fiberglass |

| Material | Stainless Steel |

Comprehensive Filtration Capabilities

Our Micron Cartridge Filter covers a broad spectrum of filtration requirements, suitable for air, gas, and liquid purification. Its adaptable design with a mesh range from 1 to 12,000 and customizable pore sizes ensures reliable removal of particles from diverse process streams, supporting applications in industrial, commercial, and laboratory settings.

Flexible Dimensions and Sealing Options

Featuring diameters between 251,000 mm and lengths from 503,000 mm, our cartridge filters are available in non-standard shapes and sizes upon request. Multiple sealing options such as gasket and O-ring enable secure and leak-proof operations, delivering maximum performance and process integrity across installations.

FAQs of Micron Cartridge Filter:

Q: How do I select the appropriate Micron Cartridge Filter for my application?

A: To choose the right filter, assess your filtration needs by considering factors such as the type of fluid (air, gas, or liquid), the required mesh or pore size, and operating conditions. Our team can assist with sizing, material selection, and customization for specific industry requirements.Q: What are the main benefits of using a customizable Micron Cartridge Filter?

A: Customizable cartridge filters offer precise performance in removing contaminants, extend equipment life, and provide flexibility for unique operational demands. The ability to tailor mesh, shape, size, and sealing options ensures optimal compatibility and efficiency for various processes.Q: When should Micron Cartridge Filters be replaced or maintained?

A: Replacement or maintenance intervals depend on process fluid, particle load, and operating frequency. Regular inspection and following manufacturer guidelines are recommended to maintain consistent filtration performance and system protection.Q: Where can these cartridge filters be installed?

A: Micron Cartridge Filters are suitable for both indoor and outdoor installations in a wide range of sectors, including industrial plants, laboratories, HVAC systems, and chemical processing facilities, wherever air, gas, or liquid filtration is necessary.Q: What is the process for customizing the filter specification?

A: Customization begins with a consultation to understand your operational parameters and filtration goals. We then propose ideal mesh size, filter rating, dimensions, material, and sealing type before fabricating the filter to your specifications.Q: How should Micron Cartridge Filters be used for optimal performance?

A: Proper installation according to the provided guidelines ensures a secure seal. Routine monitoring and timely replacement or cleaning help preserve filter efficiency and prevent downtime in your air, gas, or liquid systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry