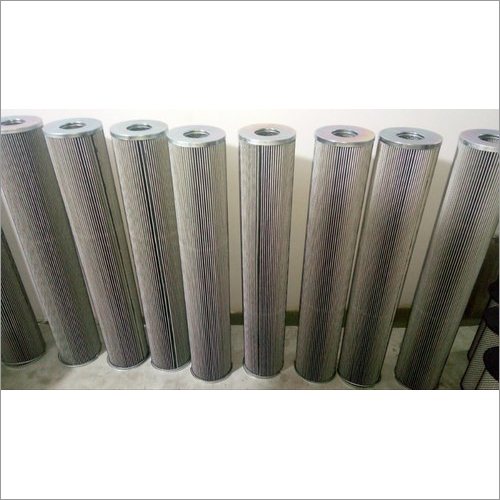

Industrial Filter Element

Price 1000.00 INR/ Piece

Industrial Filter Element Specification

- Usage

- Industrial

- Type

- Filter Felt

- Material

- Stainless Steel

- Height

- 3 Centimeter (cm)

- Product Type

- Industrial Filter Element

- Weight

- 500 Grams (g)

- Color

- Grey

- Width

- 4 Centimeter (cm)

- Length

- 9 Centimeter (cm)

- Application

- Air, Gas, Liquid

Industrial Filter Element Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujarat

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- Wooden Box, Cardboard Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001:2015

About Industrial Filter Element

Industrial Filter Element

We provide a variety of Industrial Filter Element that is extensively used in industries for various applications including oil filtration, debris removal from air, water, and other liquids. Due to reliable functioning and easy operation, the offered filter element is widely demanded in the marketplace. It has got ruggedized construction and therefore, Industrial Filter Element does not degrade in quality or become inferior for the years. Clients can purchase the filter element from us at an affordable price.

Versatile Application Scope

Engineered for use with air, gas, and liquid systems, this filter element provides remarkable adaptability in various industrial settings. The integration of filter felt and stainless steel material ensures dependable performance across different processing environments, making it a practical choice for multiple filtration tasks.

Superior Durability and Performance

Constructed from premium stainless steel, the filter element resists corrosion and maintains structural integrity during prolonged use. Its grey hue and robust composition minimize wear and increase service intervals, ensuring long-term cost efficiency for your operations.

FAQs of Industrial Filter Element:

Q: How is the industrial filter element installed in existing filtration systems?

A: The filter element is designed for straightforward installation. Simply fit it into the filter housing compatible with its dimensions (3 cm height, 4 cm width, 9 cm length). Secure any attachment points as per your system requirements, and ensure all seals align to prevent leaks.Q: What materials are used in the construction of this filter element and why?

A: This filter element utilizes high-quality stainless steel and filter felt. Stainless steel provides strength and corrosion resistance, while filter felt offers excellent particle retention, making the combination suitable for rigorous industrial applications.Q: When should the filter element be replaced in an industrial setup?

A: Replacement frequency depends on usage intensity and the type of media filtered. Regular inspections are advised; typically, the element should be replaced when flow rate drops or visible clogging occurs, ensuring optimal filtration and system efficiency.Q: Where can this filter element be utilized within industrial processes?

A: It is suitable for integration in diverse sectors, including air, gas, and liquid filtration systems in manufacturing, chemical processing, and environmental service industries.Q: What is the process for maintaining this filter element?

A: Routine maintenance involves periodic removal and gentle cleaning with approved solvents to dislodge accumulated particles. Proper care extends the lifespan and maintains high filtration efficiency.Q: How does using a stainless steel filter element benefit industrial operations?

A: Employing a stainless steel filter element enhances durability, reduces the need for frequent replacements, and provides consistent filtration performance, which ultimately supports uninterrupted industrial processes and lowers maintenance costs.Q: What are the key usages of this filter element in an industrial environment?

A: The filter element is primarily used for cleaning air, gas, and liquid streams, protecting equipment from particulate contamination, and improving the quality of process outputs across various industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Elements Category

SS Filtration Elements

Minimum Order Quantity : 1 , , Piece

Product Type : SS Filtration Elements

Application : Industrial

Size : Customized

Usage : Liquid Filtration

Hydraulic Filter Element

Minimum Order Quantity : 1 Piece

Product Type : Hydraulic Filter Element

Application : Industrial

Size : Customized

Usage : Liquid Filtration

Basket Filter Elements

Minimum Order Quantity : 1 Piece

Product Type : basket element

Application : Industrial

Size : As per Design

Usage : Liquid Filtration

Oil Filter

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Industrial Filtration

Application : Industrial

Size : As per Customer Requirments

Usage : Oil Filtration, Coolant Oil, Hydraulic Oil, Lube Oil Filtration

Send Inquiry

Send Inquiry