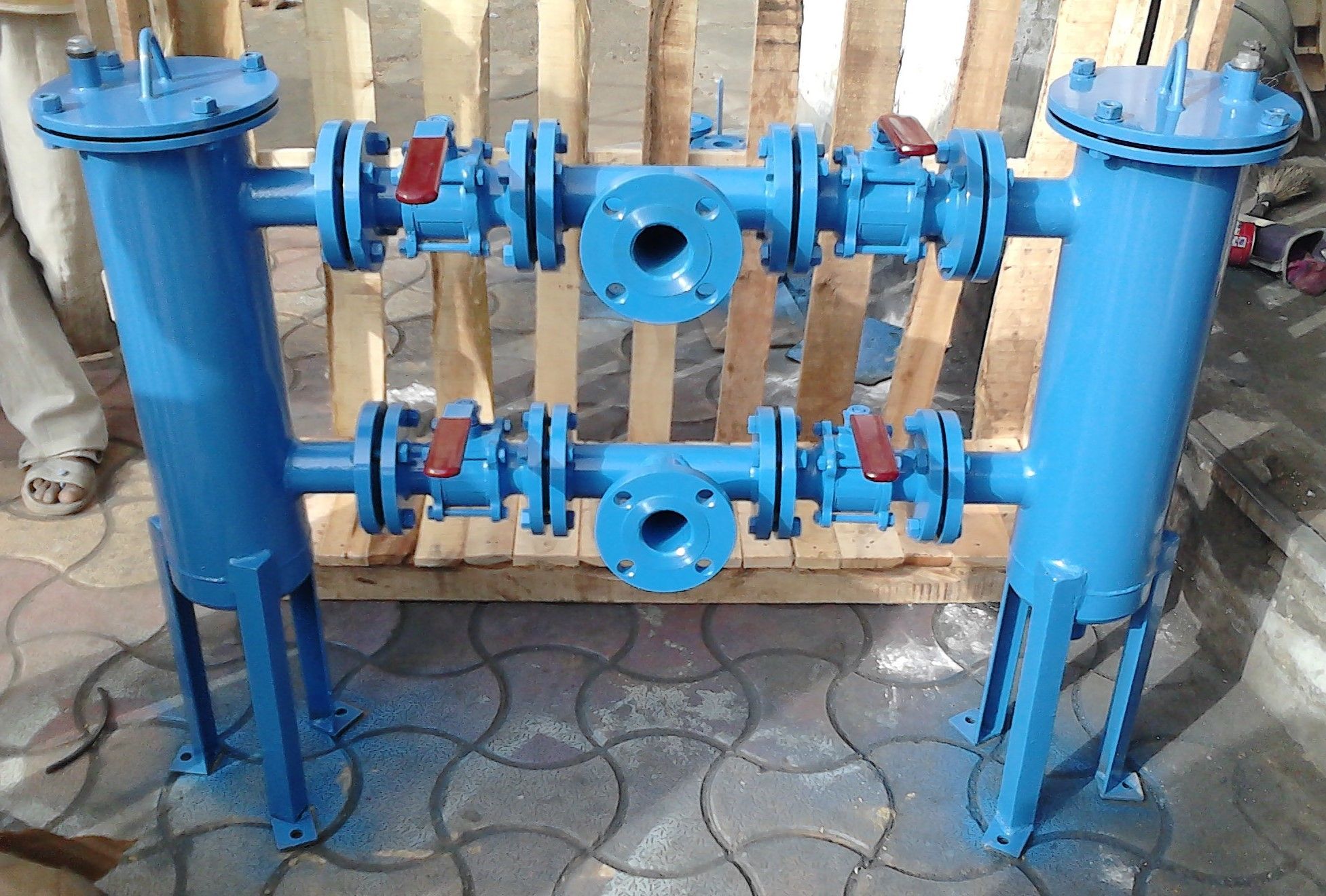

Duplex Filter Housing

Price 25000 INR/ Piece

Duplex Filter Housing Specification

- Usage

- Liquid Filtration

- Condition

- New

- Material

- CS, MS, SS304, SS304L, SS316, SS316L, SS317L

- Mesh

- 1 Micron to 6000 Micron & More

- Diameter

- 50 Centimeter (cm)

- Height

- 40 Centimeter (cm)

- Product Type

- Duplex Filter

- Construction

- Other

- Filtration Grade

- Others

- Color

- Blue

- Medium Filter

- Other

- Length

- 35 Centimeter (cm)

- Width

- 120 Centimeter (cm)

- Weight

- 20 Kilograms (kg)

- Shape

- Cylindrical

- Feature

- Cylindrical

Duplex Filter Housing Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujarat

- Payment Terms

- Cheque, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Box

- Main Domestic Market

- Assam, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, South India, Central India, Chhattisgarh, Daman and Diu, North India, East India, Arunachal Pradesh, Goa, Haryana, Kerala, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Delhi, Gujarat, Bihar, Andhra Pradesh, Odisha, West India, Karnataka, All India

About Duplex Filter Housing

Duplex FilterStrainer is used for continuous operationwithout stoppage of filtration process Duplex filter is also known as oneworking and one stand by filter Duplex Filters are available with Three wayball valve two way ball valve and butterfly valve Filter elements are easy toremove and clean We offered duplex filter with flow direction in to out or outto in as per dirt load and application We also offer back wash arrangementOur Duplex filter in MSCS MOC is available with Painted hot dip galvanizedand powder coated Duple filter in SS MOC is available with mirror polishedboth side and glass bead blasting

Duplex filter design available with us

Duplex Basket Filter

Duplex Multi Basket Filter

Duplex Pleated Basket Filter

Duplex Single Cartridge Filter

Duplex Multi Cartridge Filter

Duplex Candle Filter

Duplex Bag Filter

Duplex Multi Bag Filter

Duplex Strainer

Duplex Basket Strainer

Duplex Type Self Cleaning Filter

Jacketed Duplex Filter

Technical Parameters

Line Size NB to 30 NB

End Connections 150 300 Flanged Table E Table F Flanges DIN Standard Flanges Butt Weld

NPTBSPThreaded Hose Pipe Conn Tri Clover Adaptor SMS UnionDairy Conn

Material of Construction CS MS SS304 SS304L SS316SS316L SS317L

Operating Pressure 0 to 50 Bar

Operating Temperature 15 Deg C to 500 Deg C

Flow Rate Up to 1000 M3Hr More

Filtration Rating 05 Micron to 6000 Micron More

Top cover with nut bolts type or quick opening type

Advantages

Easy to clean

Low Pressure drop

Large area

Easy to operate and maintenance

Positive Sealing to prevent bypass

Customized design

High dirt load holding capacity

In Standard design filtration area is 4 to 6times of InletOutlet pipe area

Arrangement for back wash if required

Applications

Refineries and Petrochemicals

Power Plants

Oil Gas

Water filtration and Cooling Towers

Chemical Industries

Automobile Industries

Steel Industries Metals Minerals

Textile Industries

Dairy and Food Industries

Dyes Inks and paints Industries

Cement Industries

Fertilizers Industries

Pharmaceuticals

Coolant Oils and Cutting Fluids

Versatile Material Construction

The Duplex Filter Housing is manufactured using high-quality materials including Carbon Steel (CS), Mild Steel (MS), and various grades of stainless steel such as SS304, SS304L, SS316, SS316L, and SS317L. This extensive selection allows users to choose a unit that best matches their process requirements and chemical compatibility, ensuring safety and reliability.

Advanced Liquid Filtration

Designed for liquid filtration tasks, the duplex system supports a wide range of mesh sizes, from 1 micron up to 6000 micron. Its cylindrical design ensures even fluid distribution and minimizes pressure drops, making it appropriate for continuous filtration in industrial applications. It is ideal for use in manufacturing facilities, chemical plants, and water treatment units.

Customizable and Efficient

The housing can be customized for specific process needs, supporting different mesh sizes and material options. Its ergonomic dimensionswidth 120 cm, diameter 50 cm, height 40 cm, length 35 cmallow integration into various plant configurations without occupying excessive space. With a sturdy weight of 20 kg and blue color coding, identification and handling are simplified.

FAQs of Duplex Filter Housing:

Q: How is the Duplex Filter Housing used for liquid filtration?

A: The Duplex Filter Housing is installed in liquid processing systems where fluids are passed through internal filter meshes ranging from 1 micron to 6000 micron. This enables removal of contaminants, particles, or impurities, resulting in purified output for industrial or operational use.Q: What are the material options available for the filter housing?

A: The housing is available in multiple material choices such as Carbon Steel (CS), Mild Steel (MS), and stainless steel grades including SS304, SS304L, SS316, SS316L, and SS317L. These options provide resistance against corrosion and chemical reactions, making them suitable for demanding environments.Q: When should a duplex filter system be considered over a single filter housing?

A: A duplex filter system is preferred for continuous filtration processes, especially where the system must remain operational during maintenance or filter changes. This configuration allows one unit to operate while the other is serviced, reducing downtime significantly.Q: Where can the Duplex Filter Housing be installed?

A: This filter housing is suitable for installation in various industrial facilities such as manufacturing plants, chemical processing units, and water treatment stations across India. Its compact, cylindrical design ensures compatibility with different system layouts.Q: What is the process for selecting the correct mesh size for the application?

A: Mesh selection depends on the required filtration precision and fluid properties. For fine filtration, lower micron meshes are chosen, while larger micron sizes are used for coarse filtration. Consulting with the manufacturer or supplier helps identify the optimum mesh size for specific needs.Q: What are the benefits of using a cylindrical duplex filter housing?

A: Cylindrical duplex filter housings offer even fluid distribution, reduced pressure drop, and the advantage of uninterrupted filtering during maintenance. They accommodate a range of mesh sizes for broad filtration capability and are built for durability with high-quality materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Filters Category

Gear Oil Filter

Minimum Order Quantity : 1 Piece

Product Type : Gear Oil Filter

Usage : Industrial

Color : Yellow

Condition : New

Lube Oil Filter Element

Minimum Order Quantity : 1 Piece

Product Type : Filter Cartridge

Usage : For Oil Filtration

Color : grey

Condition : New

Stainless Steel Mesh Filter Cartridge

Price 800.00 INR / Number

Minimum Order Quantity : 1 Piece

Product Type : Filter Element

Usage : Air, Gas and Liquid Filtration

Color : Customized

Condition : New

Ss Pleated Filter Cartridge

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Filter Cartridge

Usage : Air, Gas and Liquid Filtration

Color : Customized

Condition : New

Send Inquiry

Send Inquiry