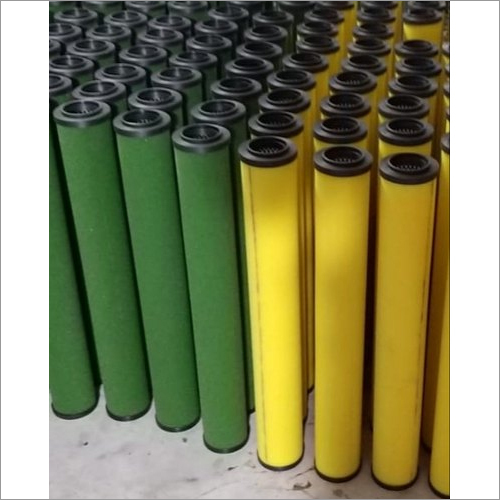

Coalescing Air Filters

Price 15000.00 INR/ Piece

Coalescing Air Filters Specification

- Usage

- Air, Gas and Liquid Filtration

- Condition

- New

- Material

- Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

- Mesh

- 0.01 Micron to 6000 Micron & More

- Diameter

- 200 Centimeter (cm)

- Height

- 140 Centimeter (cm)

- Product Type

- Coalecsing Filter

- Construction

- Other

- Filtration Grade

- Pre Filter

- Color

- Blue

- Length

- 120 Centimeter (cm)

- Width

- 180 Centimeter (cm)

- Medium Filter

- Other

- Weight

- 150 Kilograms (kg)

Coalescing Air Filters Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujarat

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 4 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Box

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Coalescing Air Filters

We offer Coalescing Filter fo r air and gas with range of removal dirt, dust, rust, condensate, moisture content, exhaust fumes and oil impurities. We design Coalescing Filter with various parameters of compressed air like flow rate, line size, operating pressure, Operating Temperature, and Filtration Rating. We offer Coalescing Filter with Aluminium, CS and SS housings. Coalescing Filter elements made of various filter medias like paper, synthetic, polyester, pp, coalescing, borosilicate glass fibre, activated carbon, HDPE, non-woven, stainless steel wire mesh, sintered bronze, sintered wire mesh and sintered powder. We also offer scrubber system for moisture separation from air and gas.

Air/Gas Filter classified under below categories.

a)MS Moisture Separator

For the removal of 99% of bulk oil/water removal from the compressed air.

b)SB Pre Filtration

Sintered bronze filter elements for removal of pipe scales, bulk liquid, solid p[articles, dust down 5 micron. This filter elements available in 5, 10, 25 and above microns.

c)PF High Efficiency Fine Filter

For the removal of particles down to 1 micron including coalesced liquid water and oil, dust, providing a maximum remaining oil aerosol content of 0.5 mg/m at 21 C.

d)UF High Efficiency Oil Removal Filtration

For the removal of particles down to 0.01micron including oil aerosols, dust, providing a maximum remaining oil aerosol content of 0.01 mg/m (0.01 ppm) at 21 C efficiency 99.99% (install in series with filter type PF). [Borosilicate glass microfibers filter media which actively repel oil to reduce pressure drop and running cost to an absolute minimum.]

e)AC Activated Carbon Filtration

For the removal of vapour and hydro carbonod ours giving a maximum remaining oil content of <0.003 mg/m (<0.003 ppm) (excluding methane) at 21 C (install in series with filter type PF + UF).

Technical Parameters:

- Line Size: NB to 30 NB

- End Connections: 150# & 300# Flanged, Table E &Table F Flanges, DIN Standard Flanges Butt Weld,

- NPT/BSPThreaded, Hose Pipe Conn., Tri Clover Adaptor, SMS Union/Dairy Conn.

- Material of Construction : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

- Operating Pressure: 0 to 50 Bar

- Operating Temperature: 15 Deg. C to 500 Deg. C

- Flow Rate : Up to 80,000 NM3/Hr. & More

- Filtration Rating : 0.01 Micron to 6000 Micron & More

- Top cover with nut & bolts type or quick opening type

Advanced Construction for Superior Filtration

Our coalescing air filters are meticulously fabricated using various metals such as Aluminium, CS, MS, and premium grades of stainless steel. With mesh apertures that range from ultra-fine 0.01 micron to broader 6000 micron sizes, they effectively filter out particulates, water, oil, and gases. These pre-filters are perfect for installation in industrial setups where reliability and high efficiency are paramount.

Versatility in Dimensions and Applications

Designed with dimensions of 180 cm width, 120 cm length, 140 cm height, and a 200 cm diameter, these filters can handle substantial flows and fit a wide range of processing systems. Whether for air, gas, or liquid filtration, their flexible construction and adaptability make them an excellent option for manufacturing plants, chemical industries, and various processing sectors.

FAQs of Coalescing Air Filters:

Q: How do coalescing air filters function in air, gas, and liquid filtration?

A: Coalescing air filters use specialized mesh structures to trap and bind contaminants present in fluids or gases. Particles and tiny liquid droplets coalesce on the mesh, forming larger droplets that can be easily separated and removed, thus ensuring pure output and protecting downstream equipment.Q: What are the main materials used in the construction of these filters?

A: The filters are manufactured using Aluminium, Carbon Steel, Mild Steel, and multiple grades of stainless steel such as SS304, SS304L, SS316, SS316L, and SS317L, providing both strength and resistance to corrosion in demanding environments.Q: When should I consider using a pre-filter like this in my system?

A: You should install a pre-filter when your application demands the removal of particulates and mist before fine filtration or sensitive processes. They are essential for extending the lifespan of downstream filters and equipment in air, gas, and liquid systems.Q: Where can these coalescing filters be utilized most effectively?

A: These filters are ideal for industrial environments, including chemical processing, manufacturing plants, and facilities requiring stringent air, gas, or liquid purification. They can also be used in both indoor and outdoor installations, thanks to their robust construction.Q: What is the filtration efficiency provided by the mesh range of 0.01 to 6000 micron?

A: The broad spectrum mesh size allows these filters to capture everything from extremely fine particles (0.01 micron) to larger debris (up to 6000 micron), offering customizable efficiency to suit different industrial needs and process specifications.Q: How does the process of coalescence improve filtration performance?

A: Coalescence involves merging smaller droplets or particles into larger ones, which are easier to remove. This process significantly enhances the filters ability to separate out liquids from gases or trap particulates for more effective filtration.Q: What are the key benefits of using coalescing air filters made with high-grade metals?

A: High-grade metal construction ensures long service life, resistance to corrosion, and sustained filtration efficiency even under harsh conditions. These benefits contribute to reduced maintenance, improved process integrity, and overall cost savings for industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compressed Air Filter Category

Air Filter Housing Assembly

Minimum Order Quantity : 1 Piece

Medium Filter : Active Carbon

Construction : Cartridge Filter

Condition : New

Color : Blue

Usage : Air and Gas Filtration

Compressor Filters

Minimum Order Quantity : 1 , , Piece

Medium Filter : Other, Air / Oil mist

Construction : Other, Cylindrical welded housing

Condition : New

Compressed Air Micro Filter

Minimum Order Quantity : 1 , , Piece

Medium Filter : Other

Construction : Other

Condition : New

Color : Grey

Usage : Compressed air gas

Compressed Air Gas Filter

Minimum Order Quantity : 1 Piece

Medium Filter : Other

Construction : Other

Condition : New

Color : Yellow

Usage : Food and beverage HVAC many Industries

Send Inquiry

Send Inquiry