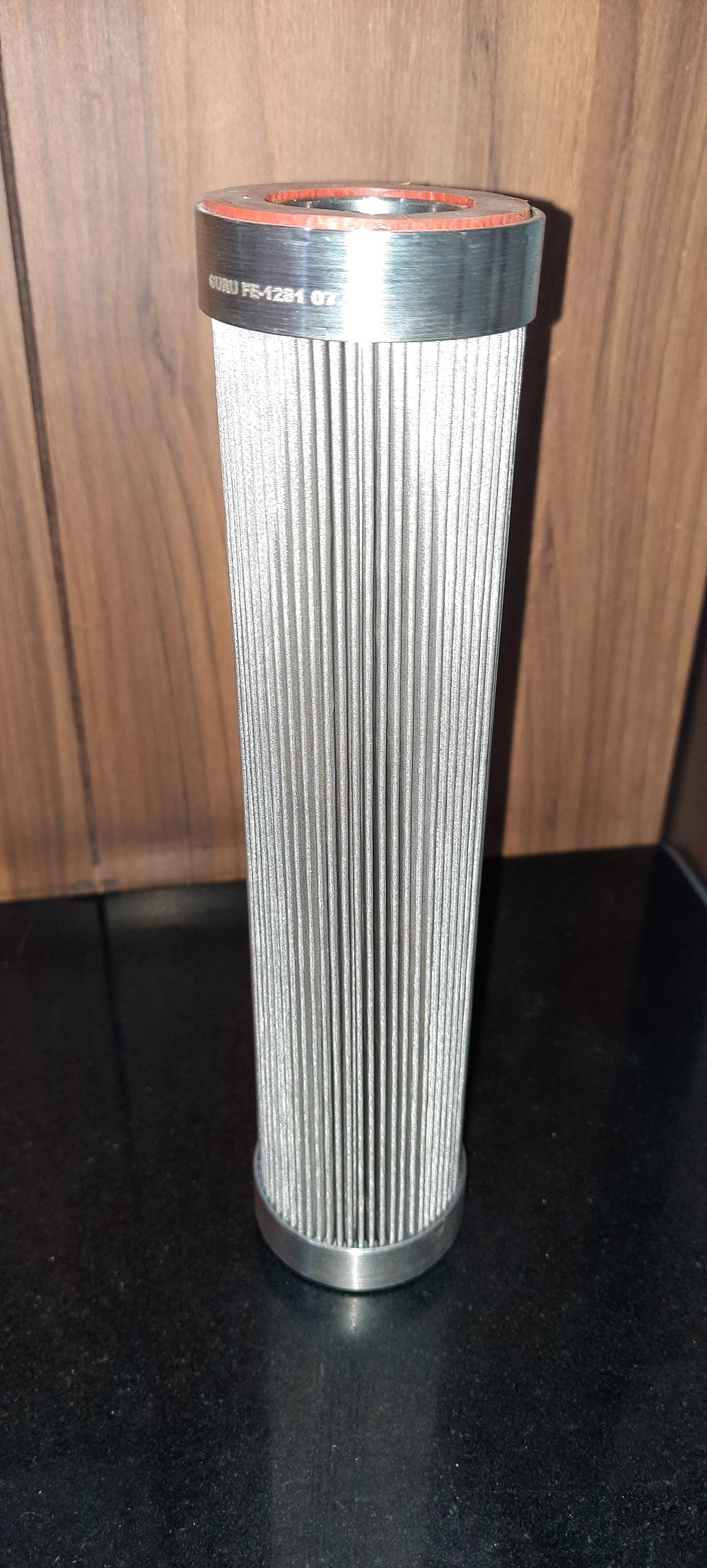

Stainless Steel Water Filter Cartridge

Stainless Steel Water Filter Cartridge Specification

- Condition

- New

- Usage

- Liquid Filtration

- Material

- CS, MS, SS304, SS304L, SS316, SS316L, SS317L

- Mesh

- 1 Micron to 6000 Micron & More

- Diameter

- 10 Centimeter (cm)

- Height

- 10 Centimeter (cm)

- Product Type

- Stainless Steel Water Filter Cartridge

- Construction

- Wire Mesh

- Color

- grey

- Filtration Grade

- Others

- Length

- 10 Centimeter (cm)

- Width

- 20 Centimeter (cm)

- Medium Filter

- Other

- Weight

- 1 Kilograms (kg)

- Shape

- Cylindrical

- Feature

- Cylindrical

Stainless Steel Water Filter Cartridge Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Gujarat

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 200 Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Cardboard Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001:2015

About Stainless Steel Water Filter Cartridge

We offer Stainless Steel Water Filter Cartridge for air liquid applications. Our Industrial Filter Cartridges are designed with various type stainless steel wire mesh, SS sintered wire mesh and SS sintered powder filter medias. This filter cartridges available in plaincy lindrical (Wrap Type) and pleated configurations to increase filtration area. We offer high temperature resistance and can withstand high differential pressure and customized design in filter cartridges. Our filter cartridges available with positive sealing like O ring, Gasket, Threaded connection, code 7 type and T Cconnection to ensure leakage. Filter cartridges made with chemical adhesive or fully welded joints. For various type of oil filtration application, we offer by pass arrangement in our filter cartridges. We also manufacture retrofit or replacement or equivalent filter cartridges

An SS filter cartridge typically refers to a filter cartridge made from stainless steel (SS), a corrosion-resistant alloy that is highly durable and suitable for various industrial applications. These cartridges are designed to filter liquids and gases by trapping solid particles or contaminants, offering efficient filtration with a long service life

Advantages:

- Low Pressure drops

- High Temperature Registration

- Leak proof

- High Dirt Holding Capacity

- Easy to clean

- High differential pressure with stand

- Ease to install and remove

- End caps with MOC of Plastic, MS, SS, Aluminium, Polyurethane, etc

- Customized design

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluidsv

Precision Filtration Across Industries

This water filter cartridge is designed to cater to precise liquid filtration needs in diverse industries such as chemical processing, pharmaceuticals, food & beverage, and water treatment. Its range of mesh sizes allows customization according to filtration requirements, making it suitable for both fine and coarse filtration tasks. With its robust wire mesh construction and superior stainless steel material options, it ensures long-term performance in demanding environments.

Robust Construction Meets Versatility

Manufactured from high-quality CS, MS, SS304, SS304L, SS316, SS316L, and SS317L materials, the cartridge resists corrosion and mechanical stress. Its cylindrical shape and compact dimensions optimize installation and maintenance processes, enhancing operational efficiency. Both exporters and suppliers support tailored solutions for varied industrial applications, allowing easy integration into existing filtration systems.

Choosing the Right Cartridge for Your Needs

With mesh options ranging from ultra-fine 1 micron to 6000 micron, customers can choose the filter most suitable for their specific liquid filtration demands. The cartridges sturdy design facilitates consistent performance, while its adaptability to multiple filtration purposes underscores its value for manufacturers and service providers alike throughout India.

FAQs of Stainless Steel Water Filter Cartridge:

Q: How is the Stainless Steel Water Filter Cartridge installed in filtration systems?

A: The cartridges cylindrical design and wire mesh construction allow for straightforward integration into most conventional liquid filtration housings. Simply insert the cartridge into the designed chamber, ensuring a secure fit for optimal filtration performance.Q: What materials are used in manufacturing the filter cartridge and why are they important?

A: The cartridge is made from CS, MS, SS304, SS304L, SS316, SS316L, and SS317L. These materials are chosen for their corrosion resistance and durability, ensuring reliable operation in various industrial and environmental conditions.Q: When should I choose a specific mesh size for my filtration needs?

A: Mesh size selection depends on the desired level of filtration. For removal of fine contaminants, opt for smaller microns like 1 micron. Higher micron sizes, such as 6000 micron, are suitable for coarse filtration applications.Q: Where can the Stainless Steel Water Filter Cartridge be used effectively?

A: It is widely utilized in liquid filtration processes across industries such as water treatment, chemicals, pharmaceuticals, and food & beverage manufacturing, primarily throughout India.Q: What is the process for maintaining and cleaning the cartridge?

A: Regular maintenance involves removing the cartridge from its housing, rinsing or backwashing with clean water to dislodge trapped contaminants, and inspecting for any signs of wear or damage before reinstalling.Q: What are the key benefits of using a stainless steel wire mesh filter cartridge?

A: Benefits include high durability, resistance to corrosive chemicals, precise filtration capabilities, and suitability for repeated cleaning and reuse, minimizing operational costs and maximizing lifespan.Q: How does the cartridges construction support different filtration requirements?

A: The wire mesh construction allows the cartridge to handle both fine and coarse particulate removal, while its range of mesh sizes and robust material options provide flexibility and reliability for a broad spectrum of industrial filtration challenges.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Filters Category

Oil Mist Filter Element

Minimum Order Quantity : 1 Piece

Material : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

Condition : New

Color : Grey, Customized

Usage : Air, Gas and Liquid Filtration

Stainless Steel Wire Mesh Filter Cartridge

Price 8000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

Condition : New

Color : blue

Usage : Air, Gas and Liquid Filtration

Hydraulic Cylindrical Oil Filter

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : SS,MS

Condition : New

Color : Yellow

Ceramic Filter Cartridge

Price 1350 INR / Piece

Minimum Order Quantity : 1 Number

Material : Ceramic

Condition : New

Color : White

Usage : Air, Gas and Liquid Filtration

Send Inquiry

Send Inquiry