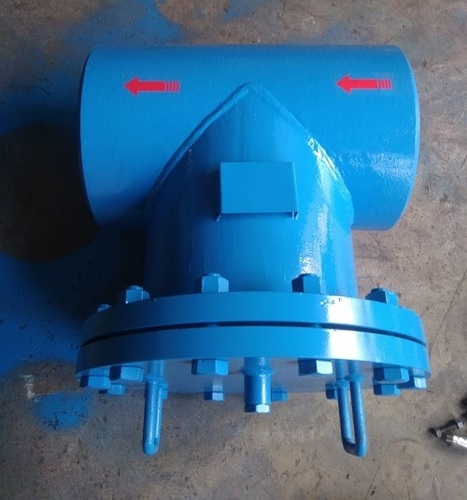

Simplex Filter Strainer

Simplex Filter Strainer Specification

- Condition

- New

- Usage

- Air, Gas and Liquid Filtration

- Material

- CS, MS, SS304, SS304L, SS316, SS316L, SS317L

- Mesh

- 1 Micron to 6000 Micron & More

- Diameter

- 9 Centimeter (cm)

- Height

- 5 Centimeter (cm)

- Product Type

- Simplex Filter Strainer

- Construction

- Wire Mesh

- Color

- Blue

- Filtration Grade

- Others

- Length

- 12 Centimeter (cm)

- Width

- 8 Centimeter (cm)

- Medium Filter

- Other

- Weight

- 5 Kilograms (kg)

Simplex Filter Strainer Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Box / Cardboard Box

- Main Domestic Market

- Dadra and Nagar Haveli, Manipur, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Daman and Diu, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Lakshadweep, Central India, West India, All India

About Simplex Filter Strainer

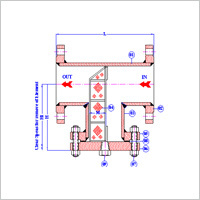

Strainer/Filter is generally used to separating coarseparticles. Strainer elements are easy to remove and clean. We offered basketstrainer with flow direction in to out or out to in as per dirt load andapplication. Bucket strainer design available with single strainer element,double cylinder type strainer element, multi strainer elements and pleated typestrainer elements. Our Bucket Strainer in MS/CS MOC is available with Painted,hot dip galvanized and powder coated. Bucket strainer in SS MOC is availablewith mirror polished both side and glass bead blasting.

Strainer design available with us

- Simplex Bucket/Basket Strainer

- Simplex Bucket/Basket Filter

- Multi Bucket/Basket Strainer

- Multi Bucket/Basket Filter

- Duplex Bucket/Basket Strainer

- Duplex Bucket/Basket Filter

- Jacketed Type Bucket Strainer/Filter

- Jacketed Type Duplex Bucket Strainer/Filter

- POT Type Strainer

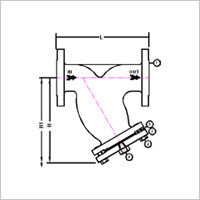

- Y Type Strainer

- Conical Strainer

- T Type Strainer

- Self Cleaning Filter

Technical Parameters:

- Line Size: NB to 30 NB

- End Connections: 150# & 300# Flanged, Table E &Table F Flanges, DIN Standard Flanges Butt Weld,

- NPT/BSPThreaded, Hose Pipe Conn., Tri Clover Adaptor, SMS Union/Dairy Conn.

- Material of Construction : CS, MS, SS304, SS304L, SS316,SS316L, SS317L

- Operating Pressure: 0 to 50 Bar

- Operating Temperature: 15 Deg. C to 500 Deg. C

- Flow Rate : Up to 1000 M3/Hr. & More

- Filtration Rating : 1 Micron to 6000 Micron & More

- Top cover with nut & bolts type or quick opening type

Advantages:

- Easy to clean

- Low Pressure drop

- Large area

- Easy to operate and maintenance

- Positive Sealing to prevent bypass

- Customized design

- High dirt load holding capacity

- In Standard design filtration area is 4 to 6times of Inlet/Outlet pipe area

- Arrangement for back wash if required

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluids

Efficient Filtration for Diverse Applications

This simplex filter strainer ensures reliable particle retention for air, gas, and liquid streams. Its wire mesh construction, offered in multiple micron ratings, guarantees adaptable filtration that meets industry demands ranging from fine to coarse separation.

Durable Construction and Versatile Material Options

Choose from a selection of materials including carbon steel, mild steel, and multiple stainless-steel grades to suit your site and fluid compatibility. The strainer is built for longevity and consistent operation in both industrial and commercial settings.

Manufactured and Supplied in India

Catering to a diverse clientele, the Simplex Filter Strainer is fabricated and traded by trusted Indian manufacturers and exporters. It serves projects throughout India and is available for import and export, meeting global standards.

FAQs of Simplex Filter Strainer:

Q: How is the Simplex Filter Strainer installed and maintained?

A: Installation of the Simplex Filter Strainer involves securely fitting it into the designated pipeline section using standard connectors. Routine maintenance primarily requires periodic cleaning or replacement of the wire mesh to preserve optimal filtration efficiency.Q: What filtration efficiency range does the strainer offer?

A: The simplex filter strainer is available with mesh ratings from 1 micron up to 6000 micron and more, enabling precise control over filtration based on your application, whether you require ultra-fine or coarse particle retention.Q: Where can the Simplex Filter Strainer be used?

A: This strainer is suitable for air, gas, and liquid filtration in industrial, commercial, and laboratory environments. Its robust design and material versatility make it applicable across multiple sectors, including chemical, pharmaceutical, and process engineering.Q: What materials are available for the Simplex Filter Strainer?

A: The filter strainer is offered in carbon steel (CS), mild steel (MS), and stainless steel grades such as SS304, SS304L, SS316, SS316L, and SS317L, ensuring compatibility with a wide range of operating conditions.Q: What are the key benefits of choosing this filter strainer?

A: Key advantages include compact size, high durability, adaptability to various filtration levels, ease of installation, and reliable performance for both fine and coarse separation in demanding settings.Q: Who supplies and manufactures the Simplex Filter Strainer?

A: The product is exported, fabricated, imported, manufactured, supplied, and traded by experienced companies based in India, providing comprehensive service and support for domestic and international customers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Strainers Category

Strainer Baskets Industrial

Price Range 5000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 Number

Construction : Other

Condition : New

Weight : 5 Kilograms (kg)

T Strainer

Price 2000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Construction : Wire Mesh

Condition : New

Weight : 2 Kilograms (kg)

Strainer Basket Stainless Steel

Price Range 6000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Construction : Wire Mesh

Condition : New

Weight : 5 Kilograms (kg)

Y Strainer

Price Range 2000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Construction : Other, Bolted cover, flanged or screwed ends

Condition : New

Weight : Varies by size typically 2 kg to 80 kg

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free