Metal Strainer Basket

Metal Strainer Basket Specification

- Usage

- Liquid Filtration

- Condition

- New

- Material

- Plastic, MS, SS, Aluminium,Polyurethane, etc.

- Mesh

- 1 Micron to 6000 Micron & More

- Diameter

- 28 Centimeter (cm)

- Height

- 42 Centimeter (cm)

- Product Type

- Basket Filter Element

- Construction

- Wire Mesh

- Filtration Grade

- Others

- Color

- Blue

- Width

- 28 Centimeter (cm)

- Length

- 40 Centimeter (cm)

- Medium Filter

- Other

- Weight

- 5 Kilograms (kg)

Metal Strainer Basket Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Gujarat

- Supply Ability

- 200 Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Cardboard Box

- Main Export Market(s)

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- Dadra and Nagar Haveli, Tripura, Andaman and Nicobar Islands, Pondicherry, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Daman and Diu, Gujarat, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Sikkim, Tamil Nadu, Telangana, Uttarakhand, Delhi, West Bengal, Rajasthan, Chhattisgarh, Uttar Pradesh, All India

About Metal Strainer Basket

We offer strainer basket for air,gas and liquid applications. Our strainer baskets are designed with varioustype of fabric, paper, synthetic, polyester, pp, coalescing, borosilicate glassfibre, activated carbon, HDPE, non-woven, stainless steel wire mesh, sinteredbronze, sintered wire mesh and sintered powder filter medias. This strainerbaskets available in plain cylindrical (Wrap Type) and pleated configurationsto increase filtration area. We offer high temperature resistance and canwithstand high differential pressure and customized design in filter elements.Strainer baskets made with chemical adhesive or fully welded joints. We alsomanufacture retrofit or replacement or equivalent filter elements.

Advantages:

- Low Pressure drops

- High Temperature Registration

- Leak proof

- High Dirt Holding Capacity

- Easy to clean

- High differential pressure with stand

- Ease to install and remove

- End caps with MOC of Plastic, MS, SS, Aluminium,Polyurethane, etc

- Customized design

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluids

Versatile Material Selection

The strainer basket is constructed from various high-quality materials including mild steel (MS), stainless steel (SS), plastic, aluminium, and polyurethane. This selection offers durability, corrosion resistance, and compatibility with an array of liquids, ensuring effective filtration even in challenging environments.

Precision Engineered for Filtration Needs

Mesh options range from 1 micron up to 6000 microns and beyond, allowing tailored filtration solutions for different applications. Whether filtering fine particulates or larger debris, this basket adapts to specific requirements in industrial, commercial, and service operations.

FAQs of Metal Strainer Basket:

Q: How do I use the Metal Strainer Basket for liquid filtration?

A: To use the Metal Strainer Basket, simply place it in the designated filtration area and pour or direct the liquid through the basket. The wire mesh captures impurities and particles according to the selected mesh size, ensuring filtered liquid output.Q: What materials are available for the Metal Strainer Basket?

A: The basket can be manufactured from plastic, mild steel (MS), stainless steel (SS), aluminium, and polyurethane, providing flexibility in handling different liquids and filtration environments.Q: When should I choose a specific mesh micron size?

A: Select the mesh micron based on the level of filtration required. For fine filtration, use lower micron sizes, such as 1 micron. For larger particles or coarse filtration, opt for higher micron sizes, up to 6000 micron or more.Q: Where can I source the Metal Strainer Basket in India?

A: You can obtain this product from the listed exporter, fabricator, importer, manufacturer, service provider, supplier, and trader. They offer reliable supply within India for various industrial sectors.Q: What is the manufacturing process of the basket?

A: The basket is fabricated using precision wire mesh construction, involving material selection, cutting, weaving or welding the mesh, assembling the frame, and finishing with quality checks to meet industry standards.Q: What are the main benefits of using this strainer basket?

A: Using this basket ensures highly efficient liquid filtration, extended durability due to robust materials, flexibility with mesh sizes for various filtration applications, and ease of maintenance and cleaning.Q: How can the Metal Strainer Basket benefit my industrial process?

A: It improves process reliability by providing consistent, high-quality filtration, reduces downtime, and offers longevity due to its strong build, contributing to overall operational efficiency in liquid handling systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Strainers Category

Strainer Basket Stainless Steel

Price Range 6000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Mesh : 1 Micron to 6000 Micron & More

Filtration Grade : Others

Material : Plastic, MS, SS, Aluminium,Polyurethane, etc.

Stainless Steel Strainer Basket

Price Range 12000.00 - 20000.00 INR / Piece

Minimum Order Quantity : 1 Number

Mesh : 1 Micron to 6000 Micron & More

Filtration Grade : Pre Filter

Material : Plastic, MS, SS, Aluminium,Polyurethane, etc.

Water Strainer Filter

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Mesh : 1 Micron to 6000 Micron & More

Filtration Grade : Pre Filter

Material : CS, MS, SS304, SS304L, SS316, SS316L, SS317L

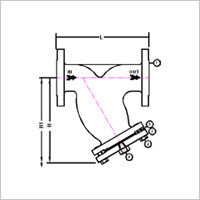

Y Strainer

Price Range 2000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Mesh : 304/316 Stainless Steel, mesh size 20 to 5000 microns

Filtration Grade : Other, Industrial

Material : Cast Iron, Stainless Steel, or Bronze

Send Inquiry

Send Inquiry