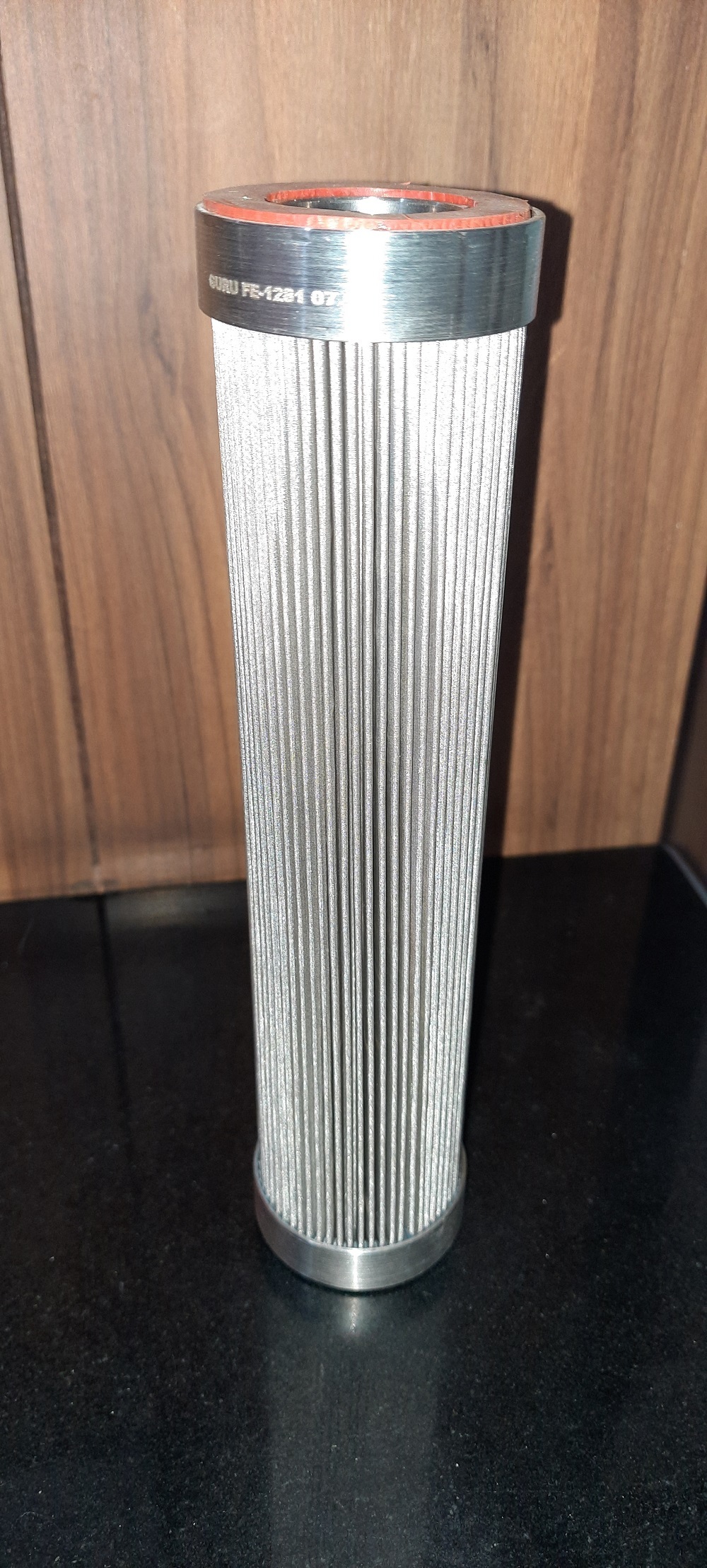

Pleated Stainless Steel Filter Cartridge

Pleated Stainless Steel Filter Cartridge Specification

- Condition

- New

- Usage

- Air, Gas and Liquid Filtration

- Material

- Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

- Mesh

- 1 Micron to 6000 Micron & More

- Height

- 22 Centimeter (cm)

- Product Type

- Filter Cartridge

- Construction

- Wire Mesh

- Color

- Grey

- Medium Filter

- Other

- Width

- 25 Meter (m)

- Length

- 10 Centimeter (cm)

- Weight

- 2 Kilograms (kg)

Pleated Stainless Steel Filter Cartridge Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 200 Pieces Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Cardboard Box

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Pleated Stainless Steel Filter Cartridge

We offer SS filter cartridge for air, gas and liquid applications. Our Industrial Filter Cartridges are designed with various type stainless steel wire mesh, SS sintered wire mesh and SS sintered powder filter medias. This filter cartridges available in plain cylindrical (Wrap Type) and pleated configurations to increase filtration area. We offer high temperature resistance and can withstand high differential pressure and customized design in filter cartridges. Our filter cartridges available with positive sealing like O ring, Gasket, Threaded connection, code 7 type and T Cconnection to ensure leakage. Filter cartridges made with chemical adhesive or fully welded joints. For various type of oil filtration application, we offer by pass arrangement in our filter cartridges. We also manufacture retrofit or replacement or equivalent filter cartridges.

Advantages:

- Low Pressure drops

- High Temperature Registration

- Leak proof

- High Dirt Holding Capacity

- Easy to clean

- High differential pressure with stand

Versatile Filtration Solutions

Crafted to handle filtration of air, gas, and liquids, this cartridges pleated wire mesh design accommodates everything from fine particulates to larger debris. Its wide micron range and sturdy materials guarantee compatibility with many industrial processes, ensuring reliability and adaptability.

Durable Construction for Demanding Environments

Manufactured using high-quality metals such as stainless steel variants, MS, CS, and aluminium, the filter stands up to tough industrial conditions. The pleated structure increases filtration surface area while maintaining structural integrity, contributing to longer operational life and reduced maintenance.

FAQs of Pleated Stainless Steel Filter Cartridge:

Q: How does the pleated design improve filtration efficiency in this stainless steel filter cartridge?

A: The pleated construction increases the filters surface area, allowing for greater particle capture and higher flow rates. This means more contaminants are removed with less pressure drop, making the cartridge both efficient and cost-effective for prolonged use.Q: What materials are used to make this filter cartridge, and how do they benefit the end user?

A: The filter is available in several robust materials, including Aluminium, CS, MS, SS304, SS304L, SS316, SS316L, and SS317L. These choices enhance corrosion resistance, withstand high temperatures, and adapt to a range of chemical environments, ensuring long-lasting filtration performance.Q: When should this filter cartridge be replaced or maintained?

A: Replacement or maintenance depends on operating conditions, contaminant load, and application. Generally, regular inspection is recommended, and the filter should be cleaned or replaced when differential pressure increases or filtering capacity diminishes.Q: Where can this filter cartridge be used effectively?

A: It is suitable for use in air, gas, and liquid filtration systems across numerous industries, such as petrochemicals, pharmaceuticals, food processing, and water treatment plants, especially where robustness and versatile filtration are required.Q: What is the filtration range of this cartridge, and how does it impact the process?

A: The filter can be configured from 1 micron to 6000 micron mesh sizes, allowing tailored filtration based on application. This adaptability ensures efficient removal of particulates, whether fine or coarse, optimizing protection for downstream processes and equipment.Q: How is the filter cartridge installed within a filtration system?

A: Installation typically involves fitting the cartridge into a compatible filter housing. Given its standard dimensions and lightweight design (2 kg), it can be easily handled and secured, ensuring a tight seal for effective filtration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Filters Category

Oil Mist Filter Element

Minimum Order Quantity : 1 Piece

Condition : New

Product Type : Filter Cartridge

Material : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

Usage : Air, Gas and Liquid Filtration

Hydraulic Oil Filter Element

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Product Type : Filter Cartridge

Material : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

Usage : For Oil Filtration

Industrial SS Process Filters

Price 8000.00-400000.00 INR / Piece

Minimum Order Quantity : 1 Number

Condition : New

Product Type : Cartridge Filter

Material : CS, MS, SS304, SS304L, SS316, SS316L, SS317L

Usage : Air, Gas and Liquid Filtration

Stainless Steel Wire Mesh

Price 1000.00-40000.00 INR / Piece

Minimum Order Quantity : 1 Number

Condition : New

Product Type : Filter Cartridge

Material : Aluminium, CS, MS, SS304, SS304L,SS316, SS316L, SS317L

Usage : Air, Gas and Liquid Filtration

Send Inquiry

Send Inquiry