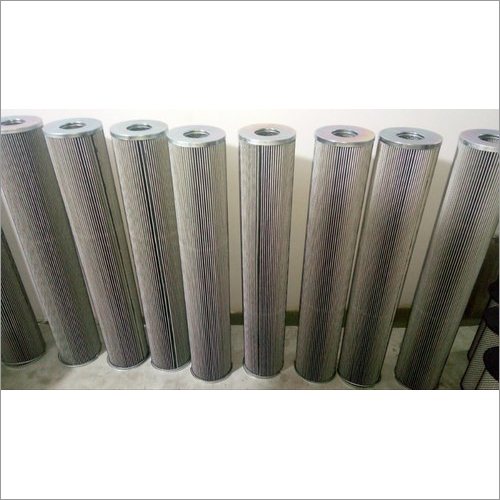

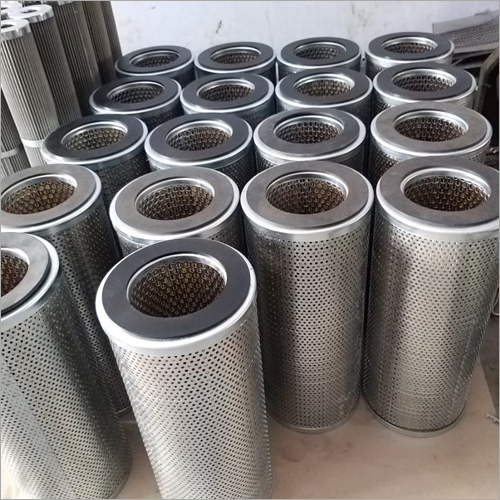

Oil Filter Element

Price 500 INR/ Piece

Oil Filter Element Specification

- Efficiency (%)

- As per Customer Requirment

- Usage

- Oil Filtration

- Size

- As per Customer Requirment

- Product Type

- Cartridge Element

- Working Temperature

- Up to 500 Deg. C Celsius (oC)

- Application

- Industrial Filtration

Oil Filter Element Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 2 Week

- Packaging Details

- Cardboard Box, Wooden Box

- Certifications

- ISO 9001:2015

About Oil Filter Element

We offered Oil Filter Element with various type of fabrics, paper, synthetic, polyester, pp, coalescing, borosilicate glass fibre, non-woven, stainless steel wire mesh and sintered wire mesh filter medias. This oil filter element available in plain cylindrical (Wrap Type) and pleated configurations to increase filtration area. We offer high temperature resistance and can withstand high differential pressure and customized design in oil filter element. Our oil filter element available with positive sealing like O ring, Gasket, Threaded connection, code 7 type and TC connection to ensure leakage. Oil Filter Element made with chemical adhesive or fully welded joints. For various type of oil filtration application, we offer bypass arrangement in our oil filter elements. We also manufacture retrofit or replacement or equivalent oil filter elements.

- Low Pressure drops

- High Temperature Registration

- Leak proof

- High Dirt Holding Capacity

- Easy to clean

- High differential pressure with stand

- Ease to install and remove

- End caps with MOC of Plastic, MS, SS, Aluminium, Polyurethane, etc

- Customized design

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluids

Product details

| Length | 10-30 inch |

| Usage/Application | Industrial |

| Outer Diameter | 6 - 15 inch |

| Filter Media | Paper, Glass Fiber, Wire Mesh, Polyester, etc. |

| Brand | Guru |

| Material | Aluminium, MS, SS |

| Efficiency | 98% |

Exceptional Heat Resistance

Designed to operate efficiently at temperatures reaching up to 500C, this oil filter element offers superior thermal stability. Its robust construction ensures dependable filtration, even under extreme manufacturing or processing conditions, making it suitable for a wide array of industrial settings where high temperatures are routine.

Customizable for Versatile Needs

The oil filter element can be tailored in both size and filtration efficiency, based precisely on customer specifications. This flexibility accommodates unique system requirements and ensures optimal compatibility, assisting industries to maintain peak operational performance and meet distinct process demands.

FAQs of Oil Filter Element:

Q: How is the oil filter element used in industrial filtration systems?

A: The oil filter element is installed within industrial filtration systems to efficiently remove contaminants from oil, thus ensuring the purity and reliability of lubricants and hydraulic fluids in various machinery and processes.Q: What is the maximum working temperature of this oil filter element?

A: The filter element is rated for continuous operation at temperatures up to 500 degrees Celsius, making it suitable for high-heat environments where standard filters might fail.Q: When should the oil filter element be replaced?

A: Replacement intervals depend on system usage and contamination levels, but it is recommended to inspect and replace the filter element during scheduled maintenance or when a drop in filtration efficiency is observed.Q: Where can the oil filter element be applied?

A: This product can be utilized in a wide range of industrial applications, including manufacturing plants, processing facilities, hydraulic systems, and any sector requiring high-performance oil filtration.Q: What is the process for customizing the filter elements size and efficiency?

A: Customers can specify their required size and desired filtration efficiency, and the manufacturer will design and fabricate the filter element accordingly to meet these specific needs.Q: How does using this filter element benefit industrial operations?

A: By delivering precise filtration at high temperatures, the filter element protects critical equipment, reduces downtime, and increases overall system longevity, which translates to cost savings and improved productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Elements Category

SS Filtration Elements

Minimum Order Quantity : 1 , , Piece

Efficiency (%) : 80

Size : Customized

Application : Industrial

Usage : Liquid Filtration

Steel Filter Elements

Minimum Order Quantity : 1 Piece

Efficiency (%) : 99

Size : Customized

Application : Industrial

Usage : Air, Gas, Liquids

Basket Filter Elements

Minimum Order Quantity : 1 Piece

Efficiency (%) : 90%

Size : As per Design

Application : Industrial

Usage : Liquid Filtration

Oil Filter

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Efficiency (%) : As per Customer Requirments

Size : As per Customer Requirments

Application : Industrial

Usage : Oil Filtration, Coolant Oil, Hydraulic Oil, Lube Oil Filtration

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free