Industrial Filtration Systems

MOQ : 1 Piece

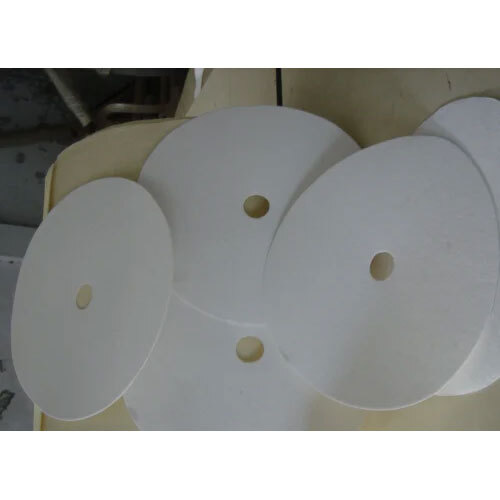

Industrial Filtration Systems Specification

- Capacity

- Up to 50,000 m/hr

- Diameter

- 100-600 mm

- Resistance

- Low Pressure Drop

- Efficiency (%)

- 99.9%

- Type

- Modular/Cartridge/Panel/Basket

- Material

- Stainless Steel, Mild Steel, Aluminum, Polypropylene

- Thickness

- 10-50 mm

- Thermal Shrinkage

- <1.5%

- Working Temperature

- Up to 120C

- Application

- Industries, HVAC, Pharmaceutical, Food Processing, Power Plants

Industrial Filtration Systems Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

About Industrial Filtration Systems

This Industrial Filtration System is made of 304/316 L grade stainless steel. Offered with sand blasting treated or polished surface, this filtering solution is equipped with flange connected outlet and tri-clamp attached inlet. Standard of its inlet and outlet conforms to global norms. This industrial item is mainly used for high viscosity fluids that include sugar based syrup, edible oil and paint etc. Excellent flow rate, high pressure and high temperature enduring capacity, ease of cleaning and standard diameter of bag are the key characteristics of this product. We are a distinguished manufacturer and exporter of premium quality Industrial Filtration System.

Advanced Construction for Robust Performance

Our filtration systems utilize galvanized, stainless steel (SS304/SS316), and other high-grade materials for unparalleled durability. With thickness ranging between 10 and 50 mm, these systems withstand tough industrial environments while minimizing thermal shrinkage (<1.5%). Polyurethane or epoxy sealants ensure long-term leak-proof operation.

Versatile Installation and Operation

Choose between vertical or horizontal installations to match your facility layout. End connections are offered in both flanged and threaded formats, providing easy integration with existing pipelines. Cleaning processes can be tailoredmanual, automatic, or backwashbased on your operational needs.

Comprehensive Application Coverage

These filtration units serve a broad spectrum of industries including HVAC, pharmaceuticals, food processing, and power generation. With modular, cartridge, panel, and basket types available, they handle flow rates up to 50,000 m/hr, delivering low pressure drop and consistently high filtration efficiency. Their adaptability ensures optimal performance across diverse environments.

FAQs of Industrial Filtration Systems:

Q: How do industrial filtration systems achieve a filtration rating between 1 to 100 microns?

A: Filtration systems utilize advanced media and precision-engineered frames made from galvanized steel or stainless steel to capture particles as small as 1 micron while permitting flow rates suitable for heavy industrial use.Q: What cleaning methods are available for these filtration systems?

A: These systems can be cleaned through backwash processes, manual procedures, or fully automatic cycles, allowing maintenance teams to select an option that best fits their operational schedules and facility requirements.Q: When should I choose flanged versus threaded end connections?

A: Flanged connections are ideal for large-scale and high-pressure installations, while threaded connections suit smaller systems or applications requiring easy removal and routine maintenance.Q: Where can these filtration units be installed in an industrial facility?

A: The systems are designed for both vertical and horizontal installation, making them adaptable to various sites such as production lines, HVAC systems, cleanrooms, and process water circuits.Q: What is the process for customizing filtration systems for specific industry needs?

A: Clients can specify filtration ratings, frame materials (such as SS304 or SS316), sealants, colors, and types (modular, cartridge, etc.), enabling each unit to meet unique operational requirements and local standards like ISO or CE certification.Q: How does the filtration system benefit operations in pharmaceuticals and food processing?

A: With high efficiency (99.9%), low pressure drop, and capacity up to 50,000 m/hr, these systems ensure contaminant-free environments, essential for regulatory compliance, product purity, and energy savings.Q: What makes the filtration system resistant to thermal and pressure stresses?

A: The use of stainless steel, mild steel, aluminum, or polypropylene, coupled with robust sealants and construction standards, guarantees minimal thermal shrinkage and stable performance under pressures up to 10 bar and temperatures reaching 120C.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Filtration Systems Category

Industrial Resin Trap Filters

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, Plastic

Product Type : Industrial Resin Trap Filters

Color : White

Usage : Industrial

Industrial Disc Type Filter

Price 1550 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, PP, MS

Product Type : Industrial Disc Type Filter

Color : White

Usage : Automobile Industry

Industrial Filtration Solution

Price 11700 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, MS, SS

Product Type : Industrial Filtration Solution

Color : Blue

Usage : Air, Gas and Liquid Filtration

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free