Filter Elements

Price 500 INR/ Piece

Filter Elements Specification

- Efficiency (%)

- to 500 Deg. C

- Usage

- Air, gas and Liquid Filtration

- Size

- As per Customer Requirments

- Product Type

- Industrial

- Working Temperature

- Up to 500 Deg. C Celsius (oC)

- Application

- Air, Gas and Liquid Filtration

Filter Elements Trade Information

- Minimum Order Quantity

- 2 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 2 Week

- Packaging Details

- Cardboard Box, Wooden Box

- Certifications

- ISO 9001:2015

About Filter Elements

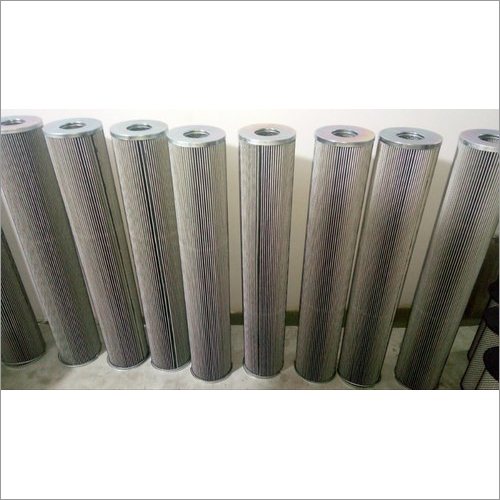

Filter Elements

We offer filter elements for air, gas and liquid applications. Our Filter Elements are designed with various type of fabric, paper, synthetic, polyester, pp, coalescing, borosilicate glass fibre, activated carbon, HDPE, non-woven, stainless steel wire mesh, sintered bronze, sintered wire mesh and sintered powder filter medias. This filter elements available in plain cylindrical (Wrap Type) and pleated configurations to increase filtration area. We offer high temperature resistance and can withstand high differential pressure and customized design in filter elements. Our filter elements available with positive sealing like O ring, Gasket, Threaded connection, code 7 type and TC connection to ensure leakage. Filter elements made with chemical adhesive or fully welded joints. For various type of oil filtration application, we offer bypass arrangement in our filter elements. We also manufacture retrofit or replacement or equivalent filter elements.

Advantages:

- Easy to clean

- Low Pressure drop

- Large area

- Easy to operate and maintenance

- Positive Sealing to prevent bypass

- Customized design

- High dirt load holding capacity

- In Standard design filtration area is 4 to 6 times of Inlet/Outlet pipe area

- Arrangement for back wash if required

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluids

Product details

| Packaging Type | Cardboard Box |

| Brand | Guru |

| Media | Air, Gas, Liquid |

| Shape | Round |

| Usage/Application | Automobile Industry |

| Material | MS, SS, Plastic |

| Particle Size | 0.01 to 6000 micron |

Versatile Filtration Solutions

Our filter elements are engineered to serve a wide range of air, gas, and liquid filtration tasks, ensuring adaptability in industries like chemical processing, environmental management, and manufacturing. Customization options allow for precise sizing, matched to the requirements of each application, delivering tailored performance for various operating environments.

High Temperature Efficiency

Built to withstand temperatures up to 500C, these filter elements excel in high-temperature filtration scenarios. This makes them suitable for challenging processes where both heat resistance and filtration precision are essential. The filtration efficiency remains uncompromised, guaranteeing consistent purity standards and reliable operation.

FAQs of Filter Elements:

Q: How are filter elements customized to meet specific customer requirements?

A: Filter elements can be tailored to precise sizes and specifications during fabrication, ensuring compatibility with unique system designs. Customers simply provide their filtration needs and dimensional criteria, and manufacturers produce the filter elements accordingly.Q: What types of applications can these filter elements be used for?

A: They are suitable for air, gas, and liquid filtration processes in industries such as chemical, pharmaceutical, food and beverage, and environmental management. Their high efficiency and temperature rating enable use in both routine and demanding filtration tasks.Q: When should I consider using filter elements rated for up to 500C?

A: These filter elements should be selected when filtration is required in environments with high operating temperatures, such as chemical reactors, gas turbines, or industrial furnaces, to ensure both safety and effective contaminant removal.Q: Where are these filter elements sourced or supplied from in India?

A: Filter elements for air, gas, and liquid filtration are available through a network of exporters, manufacturers, suppliers, and traders across India, ensuring reliable access for both large and small-scale operations.Q: What is the process for obtaining custom-sized filter elements?

A: The process involves contacting a manufacturer or supplier with your desired specifications. They collaborate closely to design, fabricate, and deliver filter elements matched to your systems needs, guaranteeing compatibility and performance.Q: How do these filter elements benefit industrial filtration systems?

A: They improve system purity, reduce maintenance needs, and support consistent operational efficiency. High-temperature resistance broadens application scope, while robust construction ensures a longer service life, optimizing productivity and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Elements Category

SS Filtration Elements

Minimum Order Quantity : 1 , , Piece

Efficiency (%) : 80

Product Type : SS Filtration Elements

Usage : Liquid Filtration

Type : Woven Filter

Hydraulic Filter Element

Minimum Order Quantity : 1 Piece

Efficiency (%) : 99

Product Type : Hydraulic Filter Element

Usage : Liquid Filtration

Type : Woven Filter

Filtration Basket

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Efficiency (%) : Up to 99%

Product Type : Industrial

Usage : Liquid Filtration

Type : Other, Filtration Basket

Industrial Filtration Basket

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Efficiency (%) : Up to 99%

Product Type : Industrial

Usage : Liquid

Type : Other, Industrial Filtration Basket

Send Inquiry

Send Inquiry