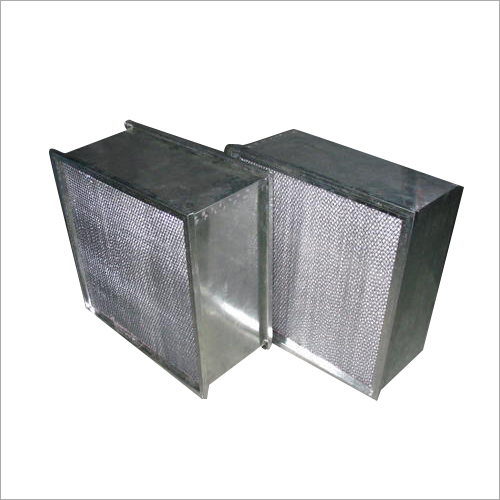

Box Type Air Panel Filter

Box Type Air Panel Filter Specification

- Capacity

- High dust holding capacity

- Efficiency (%)

- 99%

- Diameter

- Custom sizes available

- Resistance

- Initial 50 Pa

- Type

- Box Type Air Panel Filter

- Material

- Synthetic fiber / Galvanized steel frame

- Thickness

- 21 mm to 96 mm

- Thermal Shrinkage

- 1%

- Working Temperature

- Up to 80C

- Application

- HVAC systems, clean rooms, air handling units

Box Type Air Panel Filter Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

About Box Type Air Panel Filter

Product details

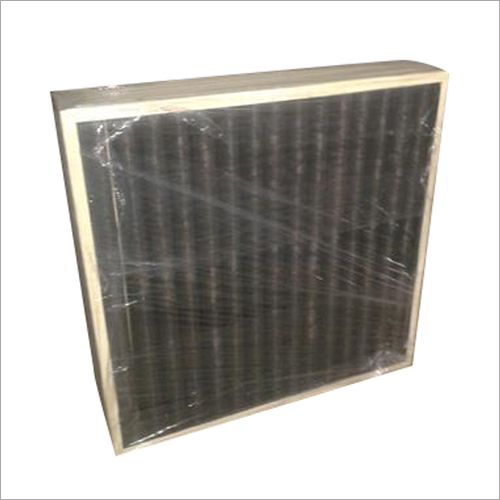

| Particle Size | 5 to 150 micron |

| Filter Medium Material | Activated Carbon,HDPE, Non-woven,Paper,Metal,Fiberglass,Microfiber |

| Usage/Application | Industrial |

| Filter Type | Panel Filter |

| Flow Rate | 500-1000 m3/hr |

| Brand | Guru |

| Material | MS, GI, SS |

High Filtration Efficiency and Durability

Designed to achieve up to 99% filtration efficiency, these air panel filters can handle high dust loads while maintaining low initial resistance ( 50 Pa). The rigid box design and PVC edge sealing enhance structural integrity and prevent air leakage, making these filters an optimal choice for environments requiring reliable performance over extended periods.

Flexible Installation and Maintenance

Box Type Air Panel Filters are compatible with both front and rear access systems, simplifying the installation process. Their service life ranges from 6 to 12 months, subject to ambient conditions, and maintenance is straightforward due to the robust construction and pleated media, which allows for easy inspection and replacement.

FAQs of Box Type Air Panel Filter:

Q: How do Box Type Air Panel Filters improve air quality in HVAC systems and clean rooms?

A: These filters utilize pleated synthetic fiber media to trap airborne dust and particulate matter efficiently, achieving up to 99% filtration efficiency. This contributes to cleaner air in applications such as HVAC systems, clean rooms, and air handling units, ensuring a healthier environment and protecting sensitive equipment.Q: What installation options are available for these air panel filters?

A: The Box Type Air Panel Filter supports both front and rear access installation, making it adaptable to various system configurations. The frame is designed for rigid mounting, ensuring stability and ease of service in commercial and industrial setups.Q: When should the filter be replaced to maintain optimal performance?

A: The recommended service life is between 6 to 12 months, depending on environmental conditions such as dust loading and humidity. Regular inspection is advised, and filters should be replaced when resistance increases significantly or visible clogging occurs to ensure continued high efficiency.Q: Where can Box Type Air Panel Filters be used effectively?

A: These filters are ideal for use in HVAC systems, clean rooms, and air handling units across industries requiring strict air quality control. Their design also suits facilities in India, with custom sizes available to accommodate specific installation needs.Q: What process is followed to maintain the filters efficiency and lifespan?

A: Routine monitoring of air resistance (pressure drop) and visual inspections are necessary. The filters should be replaced promptly when their resistance rises above recommended levels or after the maximum service interval, thus preserving a healthy airflow and effective filtration.Q: How does the pleated media benefit filtration performance and capacity?

A: Pleated media increases the surface area available for capturing dust and contaminants, resulting in higher dust holding capacity and improved filtration effectiveness. This design ensures lower initial resistance and supports longer service life compared to flat media filters.Q: What are the benefits of using a filter with PVC edge protection and galvanized steel frame?

A: PVC edge sealing prevents air bypass and enhances leak-proof performance, while the galvanized steel frame provides rigidity and resistance to corrosion. Together, these features contribute to the filters durability, minimizing maintenance and replacement costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Panel Filters Category

Panel Air Filter System

Minimum Order Quantity : 1 Piece

Material : Other

Product Type : Panel Type

Efficiency (%) : 99

Color : Black

SS Panel Filter

Price 1500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other

Product Type : Panel Filter

Efficiency (%) : 99

Color : white

Industrial Panel Type Filter

Price 1250 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Other, MS, Non Woven

Product Type : Industrial Panel Type Filter

Efficiency (%) : Up to 95%

Air Panel Filter

Minimum Order Quantity : 1 Piece

Material : Other, Synthetic fiber media, galvanized steel frame

Efficiency (%) : 98%

Send Inquiry

Send Inquiry