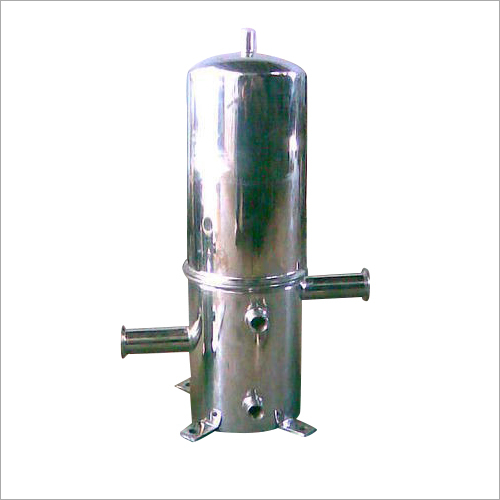

Single SS Filter Housing

Price 1000.00 INR/ Piece

Single SS Filter Housing Specification

- Filter Media

- PP/PE/SS

- Pore Size

- 5 m

- Filter Rating

- 5 Microns

- Outlet Diameter

- 1 inch Inch (in)

- Pressure

- 0.1~1.0 Mpa mpa

- Inlet Diameter

- 1 inch Inch (in)

- Shape

- Cylindrical

- Sealing

- Silicon/Viton/Gasket

- Product Type

- SS Filter Housing

- Material

- Other

- Type

- Cartridge Type

- Cartridge Style

- DOE (Double Open End)

- Diameter

- 150 mm Millimeter (mm)

- Efficiency

- 99.98%

- Application

- Liquid and Air Filtration in Industrial, Pharmaceutical, and Food Industries

- Number of Cartridges

- 1 to 10 (Customizable)

- Maximum Working Temperature

- 120C

- Mounting

- Vertical Floor Standing

- Corrosion Resistance

- High

- Gasket Material

- EPDM/Viton/PTEF

- Surface Finish

- Mirror/Matte Polished

- Vent Valve

- Provided

- End-Connections

- BSP/NPT/Flange

- Housing Height

- 10, 20, 30, 40 Inch (Configurable)

- Drain Valve

- Provided

Single SS Filter Housing Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 1 Week

About Single SS Filter Housing

SS Filter Housing provides excellent corrosion protection. It is a rugged and long-lasting filter housing and is widely demanded in the marketplace for its high dimensional stability. This product features full drainage of chambers for filter change out. It facilitates to use of both the DOE and SOE cartridges. SS Filter Housing does not degrade in quality or become interior due to chemical attacks, corrosion, and rust. We provide the filter housing in varying sizes and capacities to fulfill the diverse demands of our clients.

Product details

| Material Grade | SS304, SS316, SS316L |

| Usage/Application | Industrial |

| Brand | Guru |

| Material | Stainless Steel |

| Surface Treatment | Polished |

| Working Temperature | 30 - 120 Deg C |

| Working Pressure | 10 to 25 Bar |

Versatile Filtration for Demanding Applications

This SS Filter Housing is designed to deliver optimal filtration for both liquid and air in challenging industrial, pharmaceutical, and food processing environments. Its configurable cartridge capacity and housing height offer tailored solutions, while premium stainless steel materials guarantee excellent durability and high corrosion resistanceeven at elevated temperatures.

Configurable Design Enhances Flexibility

Choose from 1 to 10 cartridges and multiple housing heights to match your specific filtration volume and requirements. The threaded, BSP/NPT, or flanged connections simplify installation, and vertical floor standing mounting ensures stability. The systems customizable traits make it adaptable for a wide range of filtration capacities.

Reliable Performance & User-Friendly Maintenance

Featuring a mirror or matte polished finish for easy cleaning, this filter housing maintains a high standard of hygiene. Integrated drain and vent valves facilitate safe and hassle-free maintenance. EPDM, Viton, and PTFE gaskets and seals assure leak-free operation under variable pressures and temperatures.

FAQs of SS Filter Housing:

Q: How does the SS Filter Housing maintain high filtration efficiency?

A: The filter housing achieves a 99.98% filtration efficiency by using DOE-style cartridges and high-quality filter media like PP, PE, or stainless steel, with a pore size of 5 microns to effectively trap particulates from liquid or air streams.Q: What are the available customization options for cartridge number and housing height?

A: You can configure the filter housing to accommodate between 1 and 10 cartridges, with housing heights selectable at 10, 20, 30, or 40 inches to suit the required filtration volume and process demands.Q: When is it necessary to replace cartridges in the SS Filter Housing?

A: Cartridge replacement intervals depend on flow rate, contamination levels, and actual usage conditions. Typically, cartridges should be replaced when you notice decreased flow or increased differential pressure, ensuring sustained filtration quality.Q: Where is this filter housing commonly used?

A: This filter housing finds applications in industrial, pharmaceutical, and food sectors where precise liquid or air filtration is essential. Its robust and sanitary design makes it suitable for demanding environments across India and global markets.Q: What is the installation process for the SS Filter Housing?

A: Installation involves securing the housing vertically to the floor, connecting inlet and outlet pipes using BSP, NPT, or flanged ends, and ensuring all sealing gaskets (EPDM, Viton, PTFE) are properly fitted. Vent and drain valves are included to aid commissioning and maintenance.Q: How does the surface finish benefit cleaning and maintenance?

A: Mirror or matte polished surfaces reduce particulate adherence, making the housing easier to clean and maintain. The smooth finish also promotes sanitary conditions crucial for sensitive applications.Q: What advantages does stainless steel 304/316L construction bring?

A: Stainless steel 304/316L offers excellent corrosion resistance, robust mechanical integrity, and suitability for high-temperature filtration processes, ensuring long service life in harsh industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Filter Housings Category

Industrial Filter Housing

Price 3000 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Cylindrical

Filter Rating : Customized

Efficiency : Customized

Product Type : Filter Housing

Bag Filter Housing

Minimum Order Quantity : 1 Piece

Shape : Cylindrical

Filter Rating : Customized

Efficiency : Customized

Product Type : Bag Filter Housing

Stainless Steel Bag Filter Housing

Minimum Order Quantity : 1 Piece

Shape : Round

Filter Rating : 10

Efficiency : 90

Industrial SS Filter Housings

Minimum Order Quantity : 1 Number, ,

Shape : Cylindrical

Filter Rating : 40

Product Type : Industrial SS Filter Housings

Send Inquiry

Send Inquiry