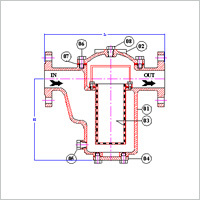

Pot Type Strainer

Price 2000.00 INR/ Piece

Pot Type Strainer Specification

- Usage

- liquid

- Condition

- New

- Material

- SS,MS

- Mesh

- 10 to 200

- Height

- 15 Centimeter (cm)

- Product Type

- POT Type Strainer

- Construction

- Other

- Filtration Grade

- Others

- Color

- yellow

- Width

- 12 Centimeter (cm)

- Length

- 10 Centimeter (cm)

- Medium Filter

- Other

- Weight

- 2 Kilograms (kg)

Pot Type Strainer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujarat

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Pot Type Strainer

Versatile Liquid Filtration Solution

Engineered for optimal performance, the Pot Type Strainer effectively filters a range of liquids, supporting processes that require clean, contaminant-free results. Its robust build in stainless steel and mild steel ensures long-lasting use, while the mesh variations (10 to 200) accommodate diverse filtration needs in manufacturing as well as processing industries.

Precision Design for Reliable Performance

With compact yet functional dimensions12 cm wide, 10 cm long, and 15 cm highthis strainer seamlessly fits into existing systems. The weight options, combined with strong construction, contribute to stability and ease of installation, making it a cost-efficient solution for industry professionals across India.

FAQs of Pot Type Strainer:

Q: How is the Pot Type Strainer installed in an industrial liquid processing system?

A: The Pot Type Strainer is designed for straightforward integration and can be installed by connecting it to the main pipeline at the required location. Secure mounting ensures stable operation and optimal filtration efficiency.Q: What materials are used in manufacturing the Pot Type Strainer and why are they chosen?

A: The Pot Type Strainer is made from high-grade stainless steel (SS) and mild steel (MS), which are selected for their corrosion resistance, strength, and durability, making them suitable for handling a variety of liquids in industrial settings.Q: When is it necessary to clean or replace the mesh in the Pot Type Strainer?

A: Cleaning or replacing the mesh should be done according to the level of contamination and frequency of usage. Regular inspection will indicate if the mesh is clogged or damaged, ensuring continued optimum performance.Q: Where can the Pot Type Strainer be sourced within India?

A: This strainer is available nationwide through various suppliers, exporters, manufacturers, service providers, and traders, making it easily accessible for industries across India.Q: What is the typical process of using the Pot Type Strainer for liquid filtration?

A: Liquids flow through the strainers mesh, which intercepts solid particles and debris as the fluid passes through, ensuring efficient contamination removal and improved product/process quality.Q: What are the main benefits of using a Pot Type Strainer with a 10 to 200 mesh range?

A: A mesh range of 10 to 200 allows tailored filtrationcoarse to fine screeningsuiting different liquid types and industry requirements, thereby enhancing operational flexibility and process integrity.Q: How does the Pot Type Strainer contribute to improved liquid handling?

A: By effectively removing unwanted particles from liquids, the strainer helps prevent equipment damage, maintains process efficiency, and meets stringent product quality standards in industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Strainers Category

Water Strainer Filter

Minimum Order Quantity : 1 Piece

Condition : New

Weight : 5 Kilograms (kg)

Medium Filter : Other

Mesh : 1 Micron to 6000 Micron & More

Metal Strainer Basket

Price Range 3800.00 - 6800.00 INR / Piece

Minimum Order Quantity : 1 Number

Condition : New

Weight : 5 Kilograms (kg)

Medium Filter : Other

Mesh : 1 Micron to 6000 Micron & More

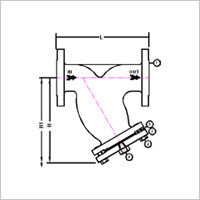

Y Strainer

Price Range 2000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Weight : Varies by size typically 2 kg to 80 kg

Medium Filter : Other, Water, oil, steam, air, gas, chemicals

Mesh : 304/316 Stainless Steel, mesh size 20 to 5000 microns

Stainless Steel Strainer Basket

Price Range 12000.00 - 20000.00 INR / Piece

Minimum Order Quantity : 1 Number

Condition : New

Weight : 10 Kilograms (kg)

Medium Filter : Other

Mesh : 1 Micron to 6000 Micron & More

Send Inquiry

Send Inquiry